Fluorspar (Calcium Fluoride – CaF2) – an important industrial mineral critical in:

Hydrofluoric acid is a key ingredient for many industrial processes and is used to produce various chemicals, including fluorocarbons, aluminum fluoride, and fluoropolymers.

Fluorspar is used as a flux to lower the melting point of raw materials in the blast furnace. It helps in removing impurities and reducing energy consumption during steel production.

Fluorspar is a key component in producing aluminum fluoride (AlF₃), which is an essential electrolyte in the smelting of aluminum.

Fluorspar is used in the glass industry to lower the melting temperature and improve the clarity of glass. In ceramics, it acts as a flux, helping to melt and blend raw materials.

It is used to manufacture various fluoride-based chemicals. The use of fluorspar in chemical processes extends to producing fluorocarbon compounds used in refrigeration, air conditioning, and fire extinguishers.

In cement manufacturing, fluorspar is added to clinker to improve the burnability and lower the energy requirements in kilns.

Fluorite is also used in optical components like lenses and prisms due to its low refractive index and dispersion properties. It is valued for its decorative and gemstone uses due to its wide range of colors.

Fluorine derived from fluorspar is an essential element in many pharmaceutical compounds and medical applications. Fluorinated drugs include a wide range of antibiotics, anesthetics, and anti-inflammatory agents.

Fluorspar is utilized as a flux in welding and other metalworking processes. It helps in cleaning and controlling the viscosity of molten metal during the welding process.

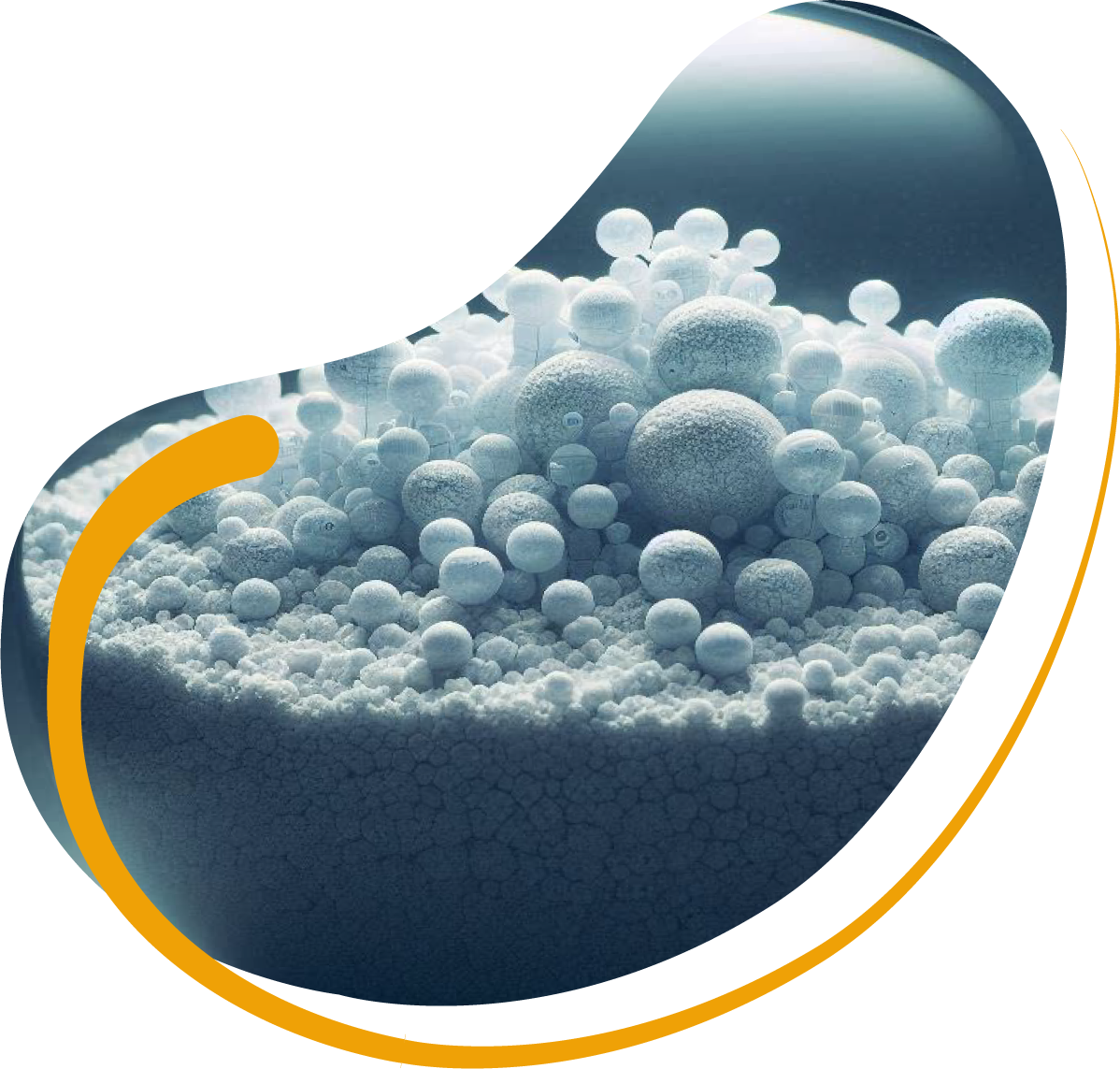

The following processed categories are available in powder/granular form:

This is the highest purity form, containing more than 97% CaF2. It is predominantly used in the chemical industry to produce hydrofluoric acid, which in turn is used to manufacture a variety of fluorocarbon chemicals, foam blowing agents, refrigerants, and other fluoride chemicals.

Contains between 85% and 96% CaF2. This grade is used in the manufacture of ceramics, specialty glass, and enamelware.

Contains between 60% and 85% CaF2. It is used mainly in the steel-making process as a flux to remove impurities from the molten metal and to improve the fluidity of slag (Geology) (Earth Magazine) (Sepfluor) (CRM Alliance).

The beneficiation of chromite ore (FeCr₂O₄), which contains chromium and iron, into Chrome Concentrate involves appropriate upgradation process. Chrome concentrate is used in metallurgical industries for the production of ferrochrome, which is a key ingredient in stainless steel manufacturing. The process for producing chrome concentrate involves:

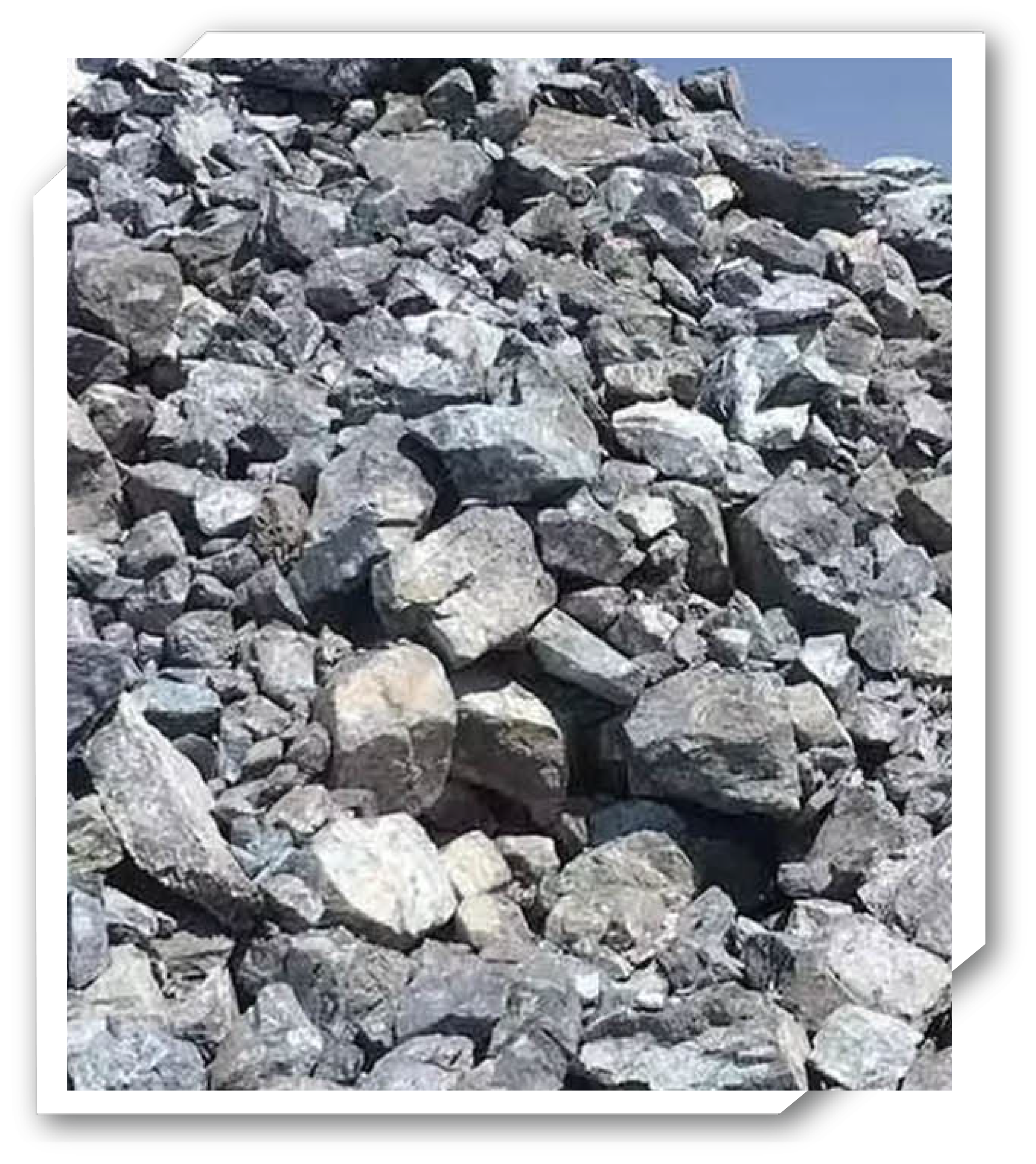

The extracted ore is initially crushed in jaw crushers to reduce it to a manageable size. Further crushing may be needed to reduce the ore to a finer size, typically using cone crushers.

The ore is ground in rod or ball mills to liberate the chromite from the surrounding gangue minerals.

The crushed and ground ore is screened into different size fractions. Coarser material is sent for further grinding, while finer material is directed to the concentration process.

Hydrocyclones or spiral classifiers are used to separate the ore into different size classes. Fine material goes to concentration, while oversized material returns for further grinding.

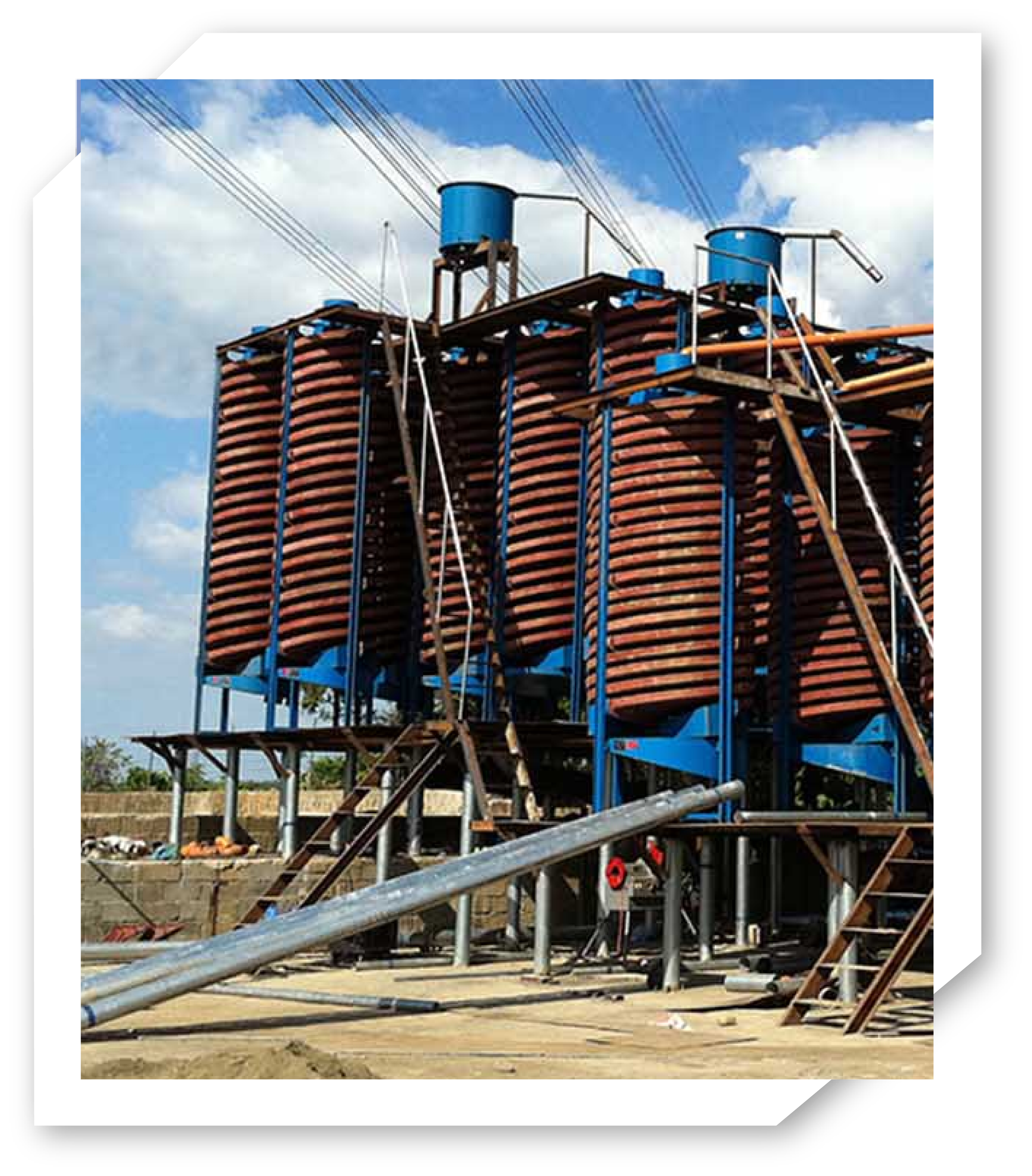

Gravity separation is one of the primary methods for producing chrome concentrate, as chromite is significantly denser than most of the associated gangue minerals. Several gravity separation techniques are used:

Chromite ore is passed through spiral concentrators, which use centrifugal force and gravity to separate the denser chromite particles from lighter gangue materials (such as silicates).

Fine chromite concentrate can also be separated using shaking tables, which exploit the difference in density between chromite and the gangue minerals.

This beneficiation process leads to a chrome concentrate that can be sold directly to the ferrochrome production industry or further processed depending on the specific requirements of the buyer.

The following processed categories are available in powder/granular form:

This grade is used primarily in the steel industry, especially for producing stainless steel. The concentrates typically have a Cr2O3 content of about 42% to 44%. This type of chromite is processed to produce ferrochrome, an alloy used to manufacture stainless steel.

These grades are used in the foundry industry for molds and cores in metal casting, and in the chemical industry for producing chromium chemicals. Foundry grade chromite usually contains a minimum of 46% Cr2O3.

The high grade concentrate is produced on special orders from clients requiring the high percentage of chrome oxide (Cr2O3) with low percentages of specific impurities. These are critical in production of high grade Alloy Steel and special purposes.

Copyright 2025 © All Rights Reserved

Designed & Developed by : Digital Hyperlinks (PVT) LTD.